A warp end may be Fitted for operating the derrick topping lift (the wire which adjusts the derrick height). Manually operated band brakes may be fitted and the drive motor will have a brake arranged to fail-safe, i.e. it will hold the load if power fails or the machine is stopped. A derrick rig, known as 'union purchase', One derrick is positioned over the quayside and the other almost vertically over the hold. Topping wires fix the height of the derricks and stays to the deck may be used to prevent fore and aft movement.

Cargo handling wires run from two winches and join at the hook. A combination of movements from the two winches enables lifting, transfer and lowering of the cargo. This is only one of several possible derrick arrangements or rigs. Although being very popular for many years, it requires considerable crew time to set up and considerable manpower for operation.

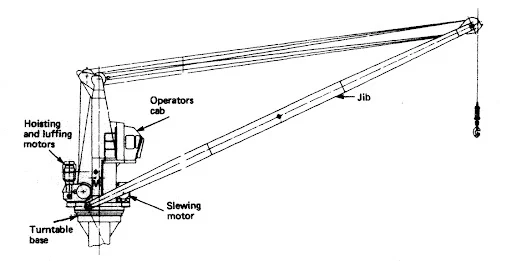

Cranes have replaced derricks on many modern ships. Positioned between the holds, often on a platform which can be rotated through 360°, the deck crane provides an immediately operational unit requiring only one man to operate it. Double gearing is a feature of most designs, providing a higher speed at lighter loads. Various types of crane exist for particular duties, for example a general duties crane using a hook and a grabbing crane for use with bulk cargoes.

Three separate drives provide the principal movements: a hoisting motor for lifting the load, aluffing motor for raising or lowering the jib, and a slewing motor for rotating the crane. The operator's cab is designed to provide clear views of all the cargo working area so that the crane operator can function alone. The crane is usually mounted on a pedestal to offer adequate visibility to the operator.

For occasional heavy loads arrangements for two cranes to work together, i.e. twinning, can be made with a single operator using a master and slave control system in the two cranes. A common revolving platform will be necessary for this arrangement. The operating medium for deck crane motors may be hydraulic or electric, utilising circuits referred to earlier.

.png)

Post a Comment