Refrigeration of cargo spaces and storerooms employs a system of components to remove heat from the space being cooled. This heat is transferred to another body at a lower temperature. The cooling of air for air conditioning entails a similar process. The transfer of heat takes place in a simple system: firstly, in the evaporator where the lower temperature of the refrigerant cools the body of the space being cooled; and secondly, in the condenser where the refrigerant is cooled by air or water.

Must read ➤ Details About Incinerator

The usual system employed for marine refrigeration plants is the vapour compression cycle. The pressure of the refrigerant gas is increased in the compressor and it thereby becomes hot. This hot, high-pressure gas is passed through into a condenser. Depending on the particular application, the refrigerant gas will be cooled either by air or water and because it is still at a high pressure it will condense.

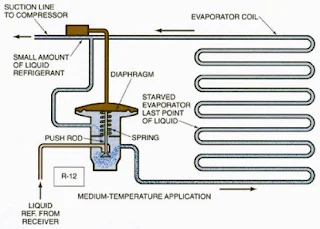

The liquid refrigerant is then distributed through a pipe network until it reaches a control valve alongside an evaporator where cooling is required. This regulating valve meters the flow of liquid refrigerant into the evaporator, which is at a lower pressure. Air from the cooled space or air conditioning system is passed over the evaporator and boils off the liquid refrigerant, at the same time cooling the air.

The design of the system and evaporator should be such that all the liquid refrigerant is boiled off and the gas slightly superheated before it returns to the compressor at a low pressure to be compressed. Thus it will be seen that heat that is transferred from the air to the evaporator is then pumped around the system until it reaches the condenser where it is transferred or rejected to the ambient air or water.

It should be noted that where an air-cooled condenser is employed in very small plants, such as provision storerooms, adequate ventilation is required to help remove the heat being rejected by the condenser. Also, in the case of water-cooled condensers, freshwater or seawater may be employed.

Fresh water is usual when a central fresh-water/sea-water heat exchanger is employed for all engine room requirements. Where this is the case, because of the higher cooling-water temperature to the condenser, delivery temperatures from condensers will be higher than that of a seawater cooling system.

.png)

Post a Comment